NEW - View LECWall Video Tutorials

Frequently Asked Questions

Here are some common customer questions and answers:What is “Tilt Potential,” as shown on the Handling screen?

LECWall estimates the degree of tilt in the panel if all the lines are on rollers and all the rollers are released. It is based on the center of gravity of the panel in relation to the center of all the lift points. This is useful for erection planning. The center of gravity of the panel is listed near the top of the Handling window. Use the C.G. to assist in locating the lift points to provide a more equal distribution of lift forces. Top of panel is shown on the left, so lifters could be positioned to induce a clockwise tilt, which would bring the top of panel up as the panel is lifted from the trailer.

While running LECWall, I came across two questions about how the program considers prestressing forces:

1. While doing a P-delta analysis, which load cases consider the axial force due to prestressing? 2. What load factor is used for prestressing force?

1. Axial force due to prestress is present for all load cases. It does not contribute to P-Delta effects directly. If prestress is eccentric and induces bow, then Delta will increase, causing a net greater P-Delta due to other applied gravity loads. Even so, the prestress force always follows the curve of the panel and is internal to the panel, so does not contribute any P-Delta force of its own.

2. No load factor is used for the prestress force (Load Factor = 1).

Reinforcing note: The reinforcing input unit is bar diameter, not area. If bar area is input by mistake, that could show the member as being under-reinforced.

When running a service load case, sometimes stresses show as red on the diagram even though the section is uncracked at that location. Why is that?

For service load cases, LECWall uses the “Allowable Service Tension Stress Coefficient” specified on the “Load Case Coefficients” screen (attached). This defaults to 5 sqrt F’c for mild reinforced members. So, although the member is not cracked, tension stresses exceed that recommended by PCI for serviceability when exposed to view and weather (see PCI Handbook, 8th Ed. Example 5.2.2.1).

How does LECWall calculate the cracking moment for a wall panel? Are any load factors included?

Self-weight, applied axial load and prestress force all increase the cracking moment. Load factors are also applied, consistent with the load case being considered. Sometimes mild steel needs to be added to satisfy the ACI 1.0Mcr requirement. Note that this criteria only applies at the location along the length of the panel where the onset of cracking is expected, not along the entire length.

How should I specify lifter locations for the situation where there are double rollers for one of the lines without a spreader bar?

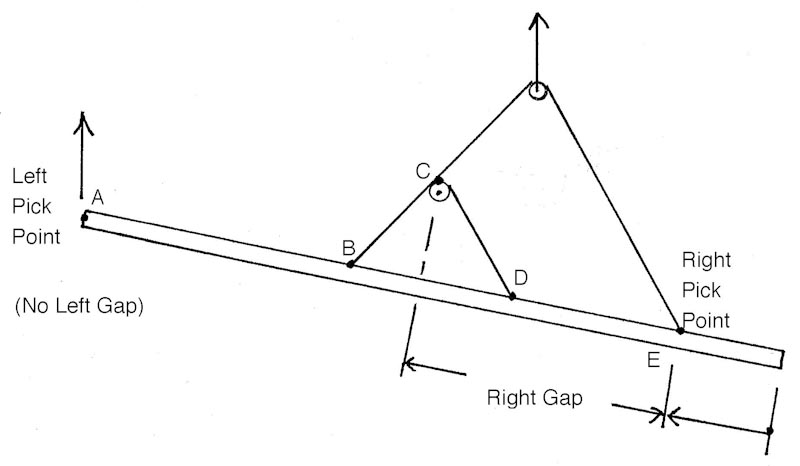

LECWall assumes two lines of support to maintain static determinacy. The pick point locations and gaps for this case can be modeled as shown in the illustration below. The left pick point A is at the top of panel. The right pick point E is as shown, measured from the right edge (panel bottom). The right gap should be the distance from the left roller centerline C to E, not from the actual lifter locations, B and D. This is conservative, but necessary to correctly model the forces in the left and right lift lines.

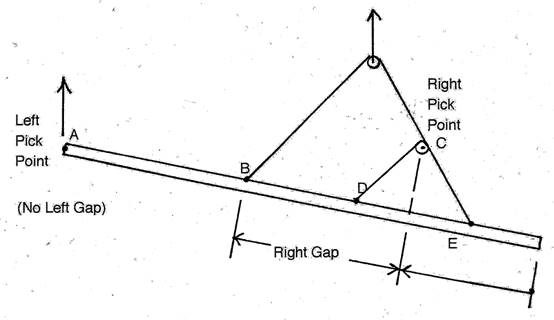

Alternate configuration with roller to the right:

The right pick point is at roller C with right gap from C to B.

LECWall gives me this message: "Second-order effects ratio is greater than 1.4."

According to ACI 318-19 6.2.5.3 (6.2.6 for ACI 318-14), ultimate moments that include second-order (P-Delta) effects should not be greater than 1.4 times the ultimate moments due to first-order effects. This provision applies to slender columns only, and only for the critical load case. LECWall checks these moments at member mid-height.

What does "Converge = True" mean on the LECWall Capacity screen?

“Converge” is related to the P-Delta effect from axial load. The analysis repeats with P-Delta deflections added until convergence occurs – where additional runs do not add additional deflection (bow). Therefore, Converge will always be true unless the panel fails with an infinite deflection. In that case, a very large deflection will display, which corresponds to the runaway deflection at the point where the analysis was stopped due to non-convergence.

When using the Beam-Spring method, why does the LECWall Capacity screen sometimes call out the section as cracked while displayed stresses are still below the cracking stress?

The stress display could be confusing in that the stress shown is from the initial analysis before the effect of P-Delta deflections and redistributions due to a cracked section. The reason LECWall doesn’t show the final stress is that this is not always a real number – cracking the panel redistributes flexural stresses to the connectors and adds additional axial tension in the tension wythe. It is a dynamic, non-linear process. For this case, the crack stress was likely exceeded in an intermediate run, then dipped down again after cracking was taken into account, reducing the wythe stiffness.